OK, so in my last entry I covered most of the work that got done while the engine was out of the car to be balanced and to repair some threads in the block. At the end of that entry, the engine had just been re-assembled and re-installed in the car. There were a few more jobs to do before I was ready to start the engine for the first time after re-installing it, though, and a few more jobs to be done after that before the car was ready to go back to the body shop.

Towards the end of a very long, rambling entry from a about a million years ago, I talked about installing the radiator for the first time, and fitting a fan shroud to that radiator. I also mentioned, in that post, that I had some concerns about the shroud I was using, and that I had considered using a "universal" fan shroud before settling on the reproduction 1965 shroud.

When I think of a fan shroud, and when you hear people attempt to troubleshoot a car with overheating problems, typically a lot of importance is placed on sealing the forward edge of the shroud to the radiator, and properly spacing the trailing edge of the shroud from the fan blades. The idea is to try to make sure that all the air going through the radiator has to go through the fan, and vice versa. The reproduction 1965 shroud was spaced well around the fan blades, but the front side of it left huge gaps where air could flow around the fan, instead of through it. It is really more of a ring suspended around the fan, rather than a shroud that constrains airflow through the radiator. The photo below shows the 1965-style shroud, removed from the car.

In the next photo below, you can see the shroud installed on the radiator, and how it leaves a lot of open area on the back of the radiator.

On the one hand, more than one million 1965 Impalas were sold, so the design of the fan shroud in 1965 must have worked OK. On the other hand, it seemed like maybe it could be made to work better.

Once I had everything out of the car, it seemed like a good opportunity to take one last stab at re-thinking the fan shroud situation. I decided to do some research, and see whether Chevrolet engineers had thought that maybe the fan shroud could be made to work better. From 1965-1970, the Impala body work saw some face-lifts, massages and tweaks, but the underpinnings were essentially the same through those years. When I searched for fan shrouds from later years, I found that the shroud for 1967-68 big block Impalas looked a lot more like what I had in mind. I didn't know for sure that it would fit the 1965 Impala, but I suspected it would. I ordered one, to find out.

As it turned out, the 1967-68 shroud fit my 1965 pretty well. The opening around the fan was at the right distance from the radiator, and it was the right size opening for the diameter of the fan I have. The flanges along the sides of the shroud, where it mounts to the radiator, were at the right width to match the radiator. The only problem was, there was a gap all along the entire width of the top and bottom edges of the shroud, maybe something like 3/8" wide. My best guess is that this was due to the fact that I was using an aluminum aftermarket radiator, and it must not have exactly the same shape as the stock factory radiator. It was advertised as being a "factory fit," but I already learned when I installed it that it wasn't perfect.

The problem with having gaps along the edges of the shroud is that it provides a path for air to flow through that gap, instead of through the radiator. The fan is trying to move some amount of air, and it's going to pull that air through the path of least resistance. There is some resistance to the airflow through the radiator, because it has to pass through all the tiny passages between the radiator fins. So the fan can pull hot air from around the engine through the gaps, which means that it is pulling less cool air from outside the car through the radiator. The shroud probably would have worked fine as it was, most of the time, but when I think about being stuck in traffic on I-35, on an August afternoon in Texas, I wanted to do everything I could to maximize the effectiveness of the cooling system.

In order to close up the gaps, I came up with a plan to use a couple pieces of angle aluminum. But first, I had to start by temporarily mounting the shroud on the radiator, with the engine and fan in place, so that I could determine where the shroud had to be located in order to properly center its opening on the fan. Then I could mark where the shroud would go on the radiator, pull the radiator out of the car, put the shroud in place on just the radiator, and start looking at what kind of shapes I would need to close off the gaps.

After getting an idea of what I needed, I just started cutting away aluminum until I was left with what I needed. There's an old saying attributed to Native Americans that, to make a canoe, you just cut down a tree and then carve away everything that isn't a canoe. Similarly, my favorite car magazine writer, David Freiburger, likes to say that to make a piece of fine art, you just start with a block of marble and chip away everything that isn't a naked woman. Starting with a length of angle aluminum, that's basically how I made these flanges.

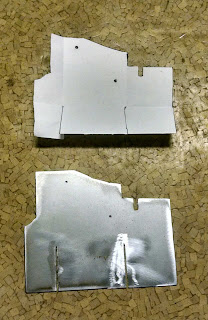

The next two photos below show the pieces I made. In the first photo, the top piece is an uncut piece of angle aluminum, to show what I started with. The lower piece in the first photo is one of the flanges I made.

The next photo shows the two pieces that I made, one for the top edge of the shroud, and one for the bottom edge.

Finally, the next photo shows the two pieces installed on the shroud. I used pop rivets to hold the aluminum flanges to the shroud.

You can see that there are two sets of mounting holes in the sides of the shroud. I would like to tell you that one set of holes was in the part when I got it, and that I added the second set of holes to correct the location of the shroud. I would like to tell you that, but I think I probably screwed up the first set of holes, and then had to make the second set. I don't really remember, though, to be honest. Looking at the locations of the holes, it kind of looks like maybe I had the shroud upside-down when I made the first set of holes, and then had to flip it over and make more holes? I don't know.

Anyway, once the radiator was back in the car, with the shroud bolted in place, you can see in the photo below, right in the middle of the photo, on the upper corner of the shroud, you can see one end of the upper aluminum flange, pop-riveted in place.

The photo below might be the best illustration of what the flange is actually doing. If you look in the gap between the aluminum radiator tank on the left, and the black fan shroud on the right (with "CAUTION" sticker on top), you can see a narrow strip of aluminum down in that gap. That is the flange, sealing off the gap.

The flanges aren't perfect, there are still small gaps here and there, especially where I had to create a relief to clear the upper radiator hose. But, I think it's a better arrangement than what I started with, anyway.

With the engine and transmission back in the car, all the fluids filled, all the connections connected, and the new fan shroud installed, etc., I was ready to start the engine again for the first time since tearing it apart for repair and balancing. The second first fire went pretty smoothly. The engine started, and ran, and stopped. It didn't leak. It didn't shake. But, there were a couple of new problems. One problem was that the engine idled poorly and seemed to have an intermittent ignition miss. The other problem was that when I tried to put the car in gear, the gears would grind as if the clutch was not disengaged.

I wanted to address the rough idle first. At idle, it sounded like the engine had an intermittent misfire, and when the engine seemed to miss, the tachometer needle would jump erratically. My buddy Allen had come down to help with the second first fire, and he used a timing light to verify that the ignition signal was cutting out whenever we heard the miss, while I sat in the car and modulated the gas pedal to keep the engine running. Neither one of us remembered having a rough idle when we did the original first fire, so I started by trying to think about what had been changed since then. There hadn't been any changes to the ignition system, so then I started checking all of the wiring connections that had been disconnected and re-connected during the engine removal and re-installation. But I couldn't find anything wrong with any of those connections.

It didn't make any sense to me, but since the issue seemed to clearly be ignition-related, I started trying to troubleshoot the ignition system. I had chosen to install a Pertronix distributor, which looks like a stock distributor but replaces the stock points with a transistorized ignition system. Because I had already double- and triple-checked all the connections, I decided to send an e-mail to Pertronix's tech support site. I wasn't expecting much help, and in fact I hadn't even ruled out the possibility that I would never get a reply at all. Seems like a lot of tech support sites are pretty useless. But, I actually got a reply the very next day. The guy said that problems like what I was describing were typically due to either power or ground issues, and he sent me a troubleshooting sheet with recommended steps.

I was astonished and delighted to have gotten a reply so quickly, but I was not real optimistic about the reply I had gotten. "Check your grounds" seems to always be the experts' (and also "experts") response when looking for help with electrical troubleshooting on automotive systems, and it rarely seems to lead to actual solutions for me. But, the nice thing about the troubleshooting sheet that the guy sent me was, they actually quantified what a "good" ground was. The sheet said that the system required no more than 0.2ohms of resistance between the ignition module and the battery ground. When I measured that resistance, I measured something like 1.6ohms.

I was still skeptical as to whether this would actually cause the symptoms I had with the car idling badly, but a very smart guy I used to work with (see also, "Paperwork") would always say, "Take away their excuses," when working on stuff like this. The idea being, when you are at someone else's mercy to make progress on your project, and they keep throwing up excuses or reasons or policies that are impeding your progress, just start taking away the excuses until there are none left. If they want you to check the thing that you already told them isn't the problem, check it anyway, so that you can move on to the next thing. If they tell you that you can't do what you're trying to do without a permit, go get the permit. And continue like that, until you get to where you're trying to go. At some point, either they'll be proven wrong and you'll all learn something new, or maybe it will turn out that they're right, but either way, you will resolve your problem.

A lot of people like to tell stories about how they proved somebody wrong in this type of situation. This is not one of those stories. In this case, it turned out that Pertronix was right. When I measured 1.6ohms between the ignition module and the battery ground, I started measuring the resistance of individual cables and components between the module and ground. The cables all had very low resistance, but the battery cut-off switch that I had installed in the dash had a resistance of 1.5ohms all by itself. I bypassed the switch, checked how the car idled, and it idled fine. Terrific news. I bought a few necessary items, re-arranged some cables, and changed the configuration of my battery cut-off switch so that now it cuts the battery positive connection, instead of the ground, and the battery ground cable runs directly to the engine block. I can now measure 0.1ohms between the ignition module and the battery ground, and the car idles fine.

So that left me with my other problem, which was that I couldn't shift the car into gear with the engine running. The clutch didn't seem to be disengaging properly.

I had had the same problem when we did the first first fire, and at the time I assumed that I had not adjusted the hydraulic throwout bearing for the clutch correctly. To try to figure out what the problem was, I got under the car with the engine shut off and the transmission in gear, and with the front of the car jacked up and the rear wheels on the garage floor. I had someone else hold the clutch pedal to the floor, and I tried to turn the driveshaft by hand. I could turn it relatively easily, although it felt like there was some drag on it. With the engine off, the transmission in gear and the clutch engaged, I should not be able to turn the driveshaft. I verified that by trying the same test with the clutch pedal released. With the clutch pedal released, I couldn't turn the driveshaft. This verified that the clutch pedal was operating the clutch, but for some reason there seemed to be some drag on the shaft, and I couldn't put the car in gear with the engine running. I thought, based on that, that maybe I had not adjusted the hydraulic throwout bearing properly, and maybe it was not traveling quite far enough to fully release the clutch, so that the pressure plate was still dragging slightly on the friction disc.

Working with that theory, after the engine came out of the car for repair, when I had everything apart, I took another look at the throwout bearing adjustment. I measured it and double- and triple-checked it every way I could think of, and it still looked to me like I had had it adjusted it correctly according to the directions. But I knew that there had been some drag on the driveshaft, and I knew that I couldn't put the transmission in gear with the engine running. As a result, I decided that I must not be measuring correctly, and I decided that when I put everything back together, I would purposely adjust the throwout bearing a little bit closer to the clutch fingers, so that it would have enough travel to fully disengage the clutch.

However, as I've already described, once everything was back together and the engine had been started again, etc., I discovered that I still couldn't shift the transmission into gear without grinding gears. The clutch still didn't seem to be disengaging properly. Getting under the car and repeating the driveshaft test with someone else operating the clutch pedal still gave the same result, as well.

Some internet searches turned up multiple stories about people who had similar symptoms, which they attributed to the clutch friction disc sticking to the pressure plate. The "fix" that everyone gave was typically something along the lines of starting the engine in gear and then disengaging the clutch and slamming on the brakes to break the friction disc loose, or something along those lines.

It didn't really make sense to me that the friction disc could be sticking to the pressure plate securely enough to keep me from putting the transmission in gear, though. For one thing, when I'd pulled the engine and transmission out of the car after the first first fire, the friction disc had dropped right out as I disassembled things. It didn't seem to be stuck to anything. And for another thing, if it was really stuck that securely, then I shouldn't be able to turn the driveshaft by hand, even with the clutch pedal depressed.

So, I started thinking, if the clutch appears to be working properly, what else can transmit friction from the engine to the input shaft of the transmission? As I thought through it, there was only one thing: the pilot bushing in the tail end of the crankshaft.

There is a bronze bushing, called the pilot bushing, which presses in to the tail end of the crankshaft, and its function is to support the front end of the transmission input shaft. It is the only thing connected to the crankshaft which should be touching anything connected to the transmission input shaft when the clutch is disengaged, so I decided that this must be the problem.

I figured there were at least three ways that I could end up with excessive friction between the pilot bushing and the input shaft: first, it could just be a tight fit; either the bushing could be a little too small, or the shaft could be a little too big. Second, the transmission could be radially misaligned with the engine, so that there was some side-force between the two. Third, the transmission could have an angular misalignment with the engine, which would also create excessive friction where the input shaft fit into the pilot bushing.

I didn't think an angular misalignment seemed likely, as the transmission should be mounted square to the engine by the bellhousing. A defective bellhousing was possible, but seemed unlikely. I was somewhat worried, however, about a radial misalignment. I talked in an earlier entry, from way back in 2014, about the process of measuring the runout when mounting an aftermarket bellhousing. And I also mentioned, in another earlier entry, that I had had some issues with easily aligning the transmission during installation. So based on all this, I was somewhat concerned that I might have fouled up the runout check, and that maybe the transmission was not properly aligned to the engine.

Anyway, I was going to have to remove the transmission from the car again in order to check for misalignment, and I wanted to set the throwout bearing adjustment back within specifications, as well. So I decided to start by pulling the transmission out of the car again.

At this point, the transmission had been in and out of the car several times, and I already knew what a hassle it was. The Muncie four-speed has a rounded bottom, and I am lazy so I always try to pull the transmission without unbolting the shifter from the side of it. I use a jack to support the weight of the transmission, but the rounded bottom combined with the weight of the shifter on the side means that the transmission is constantly trying to roll off the side of the jack. It can be pretty awkward to try to wrestle with it under the car. I wanted to come up with a better way of controlling the transmission as I maneuvered it in and out of the car, so I made a plan to create a cradle that would secure the transmission to the jack during installation and removal.

I discovered that the cradle that came with my floor jack will actually just lift out, and is only held in place by gravity.

That made it easy to start thinking about designing a cradle for the transmission, which could also just drop into that hole in the jack.

I took some measurements, took a look at McMaster-Carr's website, and I ordered some 1/4" steel plate, and a length of 1-1/8" steel rod.

Before I started cutting up my steel, though, I first wanted to make a cardboard mock-up of what my cradle would look like.

I started off with grand ideas of a cradle that would really cradle the transmission, support it in several places and keep it from rolling around. A combination of laziness and limited resources, however, motivated me to rapidly simplify, and after going through some mental revisions, I ended up with a somewhat different plan. The base of the cradle would just be a flat piece of 1/4" steel plate, with a stub of 1-1/8" steel rod extending off the bottom of it, to engage the hole in the jack. In order to keep the transmission from rolling, though, I would just make a bracket off of the steel plate, which would bolt to the bracket on the transmission where the switch for the reverse lights mounts. I always remove that switch from the transmission before removing the transmission, because the wiring for the switch runs inside the car and cannot be disconnected under the car, so the switch has to be removed if the transmission is going to be removed. That means that the bracket will always be available during transmission removal/installation.

I mocked up a cradle using cardboard for the base, and paper for the bracket that would bolt to the reverse light switch bracket.

The paper portion had to be carefully shaped, and slotted in a few locations, in order to clear some features on the transmission. I wanted to have a couple of vertical folds in it, for strength, as I was planning to use relatively thin steel sheet, and I didn't want it to just buckle under the transmission's weight.

After I had created the cardboard/paper mock-up, I disassembled it, flattened out the paper portion, and traced that onto a piece of sheet metal.

I cut that out...

...and folded it up to create the bracket I wanted. Then I bolted that to my piece of 1/4" steel plate, to form the transmission cradle.

You may have noticed that it's not real pretty. After some test-fitting on the transmission, I added some shims under the vertical bracket, to get the spacing right. You can also see two holes in the middle of the plate. I used a countersunk hole and an appropriate bolt to attach the length of steel rod that would sit in the jack, but I made in the hole in the wrong location on the first try, so I ended up with two holes.

So it's not real pretty, but it does sit in the jack...

...and it does hold a transmission:

This all took some time and effort. In addition to the planning and mock-up and cutting and assembly, just cutting through 1/4" steel plate and 1-1/8" steel rod with a 4-1/2" cut-off wheel on a Harbor Freight angle grinder requires a little bit of patience. But there is no doubt that the effort was worth it, as removing and installing the transmission was an absolute breeze compared to previous efforts.

With the transmission out of the car, I made another measurement of runout between the bellhousing and the crankshaft. It seemed to be within spec. I re-adjusted the throwout bearing back to the specified clearance, and got ready to put the transmission back in the car.

By this time, I had spent a lot of time thinking about the symptoms of my clutch problem, and what the cause might be, and I had developed a theory. My theory was that sometimes new pilot bushings are tight and need to be worn in, and also that everyone online who thought their friction disc was sticking to their pressure plate had also had tight pilot bushings, which they mistakenly assumed were sticking friction discs. Based on their descriptions of various methods of breaking their friction discs (i.e., actually their pilot bushings) loose, and based on the fact that I knew that I could turn my driveshaft by hand with the clutch disengaged, I figured it shouldn't take much force at all to get the transmission input shaft broken loose from the pilot bushing in the crankshaft.

Based on all that, I made a plan to put the transmission back in the car, and then to put the car on the floor, put it in fourth gear, hold the clutch pedal down, hold the brake pedal down, and start the engine. I figured that putting the transmission in fourth gear would give the brakes the maximum mechanical advantage over the engine. I didn't, after all, want to end up accidentally driving the car into my kitchen. I chocked the wheels, too, just in case.

This all ended up being satisfyingly anticlimactic. When I started the car, there wasn't even a hint of a lurch, or any other sign of the car trying to move forward. It just started and idled. Even better still, after letting it idle like that for a minute or so, I took it out of fourth gear, and was then able to shift it into first gear, with the engine running, for the first time. I shifted it into second, third, and back into fourth again. I shifted it into reverse. I shifted it back into first again, took a deep breath, and I let the clutch pedal up and moved the car forward a couple feet. I took it out of first gear, put it in reverse, and moved the car back a couple feet. The car had moved under its own power for the first time. A monumental achievement after more than four years of effort. There was a beer consumed that night.

There was a little bit of work still to do before I was ready to drive the car back to the body shop, and I had planned to cover that in this entry, but this seems like a good place to stop for now. More to come, next time.

Friday, November 30, 2018

Subscribe to:

Comments (Atom)